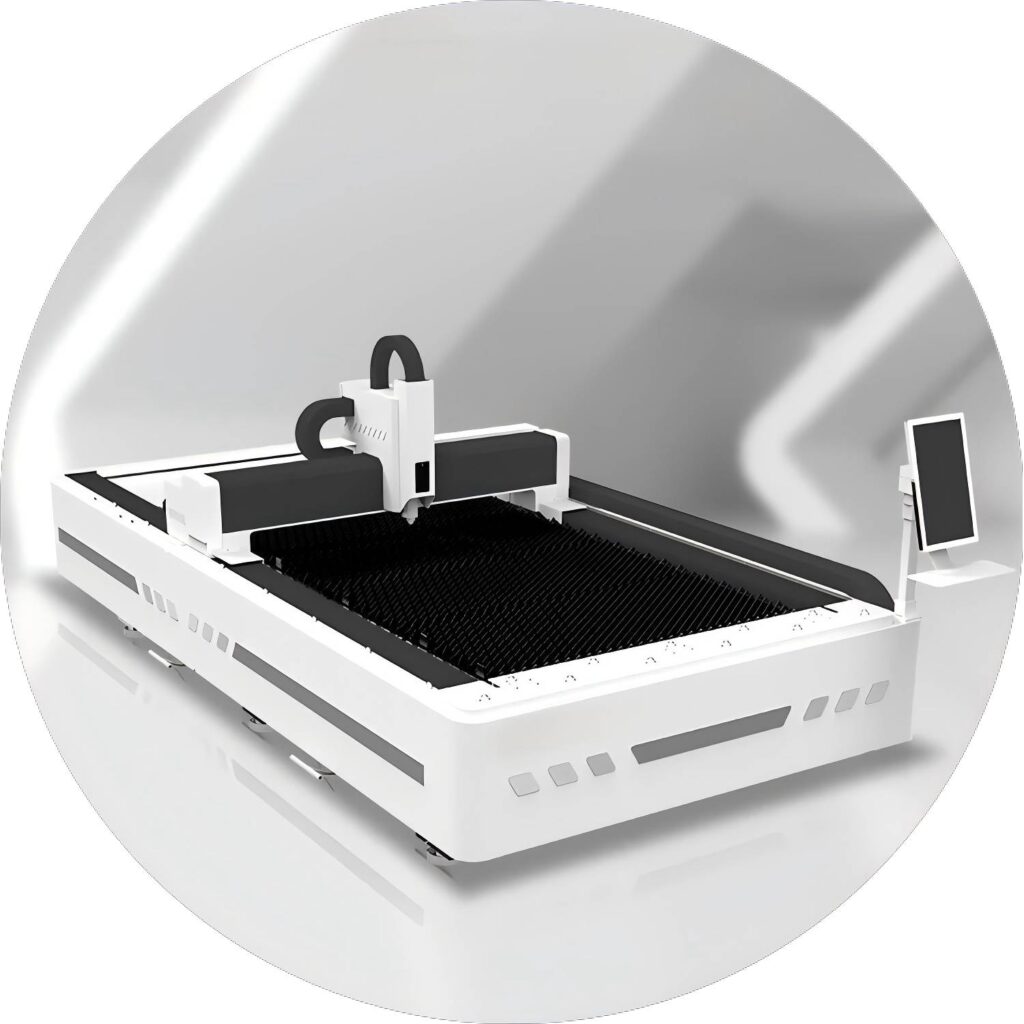

Due to the rapid development of digitalization in the metal processing industry, metal laser cutting machines have gained popularity for their fast cutting speeds, high quality, and intelligent cutting capabilities. However, can they cut all types of metal materials? Below is an analysis of the materials suitable for cutting with metal laser cutting machines.

Metal laser cutting machines are widely used in the metal processing industry due to their high speed, precision, and intelligent capabilities. They can effectively cut a variety of materials, including carbon steel, stainless steel, alloy steel, aluminum and its alloys, copper and its alloys, and titanium and its alloys.

1. Carbon Steel

The thickness of carbon steel plates that can be cut by a metal laser cutting machine depends on the power of the laser. With advanced laser technology, the beam quality is excellent, resulting in narrow kerfs and smooth cutting surfaces. For carbon steel plates under 5mm, only compressed air is needed instead of oxygen, reducing the cost of using oxygen.

2. Stainless Steel

Laser cutting is an effective tool for industries that primarily use thin stainless steel sheets as their main components. It can effectively limit the heat-affected zone on the cutting edge, thereby preserving the material’s excellent corrosion resistance.

3. Alloy Steel

Both basic alloy structural steel and alloy tool steel can achieve good cutting edges with laser cutting. Even for some high-strength materials, as long as the cutting parameters are properly controlled, straight and slag-free edges can be obtained. However, for tungsten-containing high-speed tool steels and hot-work steels, issues such as melting and slag adhesion may occur during laser cutting.

4. Aluminum and Its Alloys

Aluminum cutting operates on a melting mechanism, where the auxiliary gas is mainly used to blow away the molten material, resulting in a good cutting surface quality. For other aluminum alloys, care must be taken to prevent micro-cracks in the cutting seam.

5. Copper and Its Alloys

Pure copper (red copper) has a very high reflectivity, making it essentially unsuitable for CO2 laser cutting. Brass (copper alloy) can be cut with higher laser power and auxiliary gases such as air or oxygen, but only for thinner plates.

6. Titanium and Its Alloys

Pure titanium couples well with the heat energy converted from a focused laser beam. When oxygen is used as the auxiliary gas, the chemical reaction is intense, and the cutting speed is fast. However, an oxide layer can easily form on the cutting edge, and overheating may occur if not careful. To ensure cutting quality, it is safer to use air as the auxiliary gas. Titanium alloys commonly used in the aircraft manufacturing industry can achieve good laser cutting quality, although there may be slight slag adhesion at the bottom of the cutting seam, which is easy to remove.

The above are the commonly cut materials for metal laser cutting machines, and their cutting efficiency has also been significantly improved.

Get in Touch for Expert Guidance

Looking for the perfect laser welding solution? Contact us for expert advice! Reach out via WhatsApp or email for inquiries, quotes, and product catalogs.📞 WhatsApp: +86 18965650388

📧 Email: kelly@pilaser.com