Welcome to the ultimate guide to laser marking machines, where we delve into the world of cutting-edge technology that is revolutionizing industrial processes. With a laser’s precision and versatility, these machines are enhancing efficiency and ensuring a higher degree of accuracy in various applications.

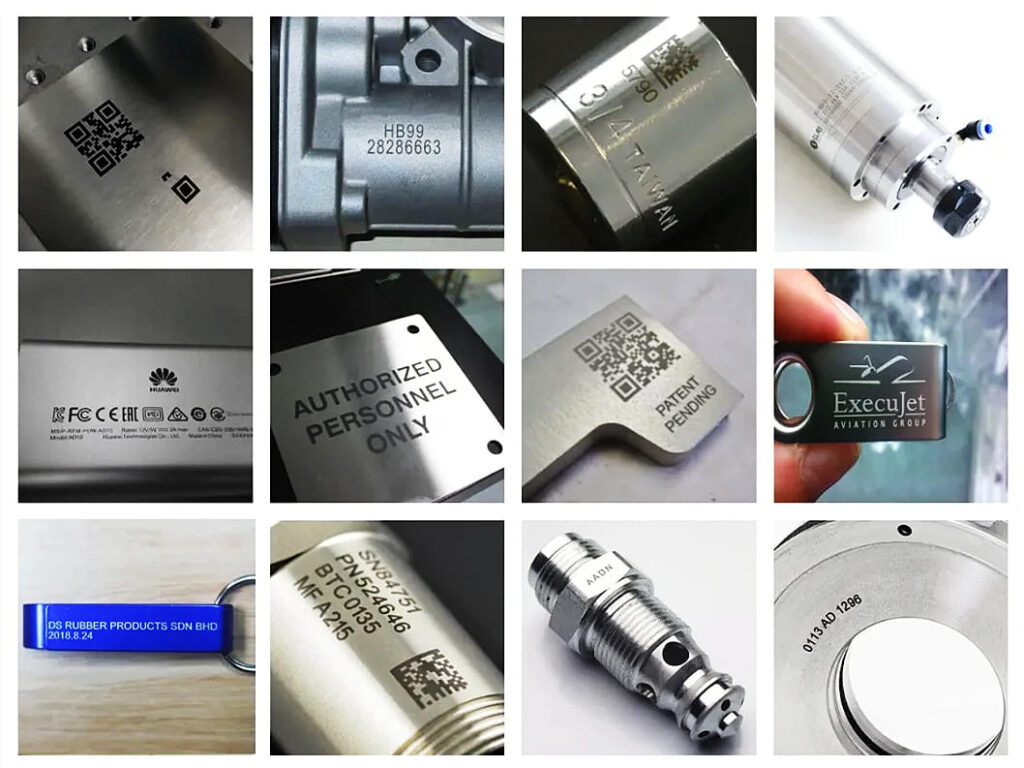

From automotive to aerospace, electronics to packaging, laser marking machines are leaving their mark on every industry. Say goodbye to traditional marking methods and hello to the incredible capabilities of laser technology. Whether you need to engrave a serial number on a metal component or create intricate designs on promotional items, laser marking machines deliver unmatched results.

In this comprehensive guide, we will explore the different types of laser marking machines available, their key features, and how they can benefit your specific industrial processes. Additionally, we will delve into the various materials that can be marked using lasers, such as metals, plastics, and even organic materials.

Join us on this transformative journey as we uncover the endless possibilities of laser marking machines and discover how they can elevate your industrial operations to new heights of efficiency and precision. Get ready to make your mark with laser technology!

1. How Laser Marking Machines Work

Laser marking machines utilize a high-powered laser beam to alter the surface of a material, creating marks, engravings, or color changes without direct contact. The process involves focusing the laser beam on the material, which results in localized heating and modification of the surface properties. Different types of lasers, such as fiber, CO2, or UV lasers, are used based on the material and the desired marking effect.

The laser beam interacts with the material by either engraving, annealing, foaming, or removing a layer of the surface. The intensity and duration of the laser pulses determine the depth and quality of the mark. Laser marking is a non-contact, non-mechanical process, which reduces wear and tear on the equipment and ensures consistent, high-quality results.

Laser marking machines can achieve high precision and resolution, making them ideal for marking intricate designs, serial numbers, barcodes, logos, and other identifiers on a wide range of materials. The flexibility and speed of laser marking machines make them indispensable in industries where efficiency and accuracy are paramount.

2. Types of Laser Marking Machines

There are several types of laser marking machines available, each suited for specific applications and materials. Fiber laser marking machines are commonly used for metal, plastic, and some non-metal materials due to their high beam quality and efficiency. CO2 laser marking machines are preferred for organic materials, wood, glass, and certain plastics.

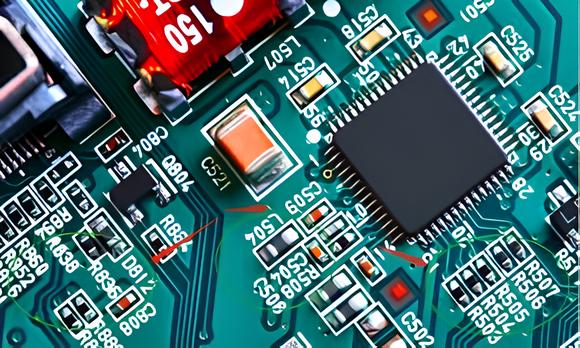

UV laser marking machines are ideal for high-precision marking on sensitive materials like semiconductors, medical devices, and electronics. Each type of laser marking machine offers unique advantages in terms of speed, precision, and compatibility with different materials. Choosing the right type of laser marking machine depends on the specific requirements of your industrial processes.

Hybrid laser marking machines, which combine different laser sources, offer versatility and flexibility in marking a wide variety of materials. These machines provide the benefits of multiple laser types in a single system, allowing for greater customization and efficiency in marking processes.

3. Applications of Laser Marking Machines in Different Industries

Laser marking machines find extensive applications across various industries, including automotive, aerospace, electronics, medical devices, packaging, and more. In the automotive industry, laser marking is used for marking engine components, chassis parts, and vehicle identification numbers (VINs) for traceability and anti-counterfeiting purposes.

Aerospace manufacturers utilize laser marking machines to mark serial numbers, part codes, and compliance information on critical components for quality control and regulatory compliance. In the electronics industry, laser marking is essential for marking PCBs, connectors, and semiconductor components with high precision and durability.

Medical device manufacturers rely on laser marking machines to apply permanent markings on instruments, implants, and surgical tools for tracking, identification, and safety purposes. The packaging industry uses laser marking for branding, labeling, and coding on various packaging materials to ensure product authenticity and traceability.

4. Advantages of Using Laser Marking Machines

The advantages of using laser marking machines in industrial processes are manifold. Laser marking offers high precision, enabling intricate designs, small text, and complex patterns to be marked with exceptional clarity and accuracy. The non-contact nature of laser marking eliminates the need for consumables like inks or dyes, reducing operational costs and environmental impact.

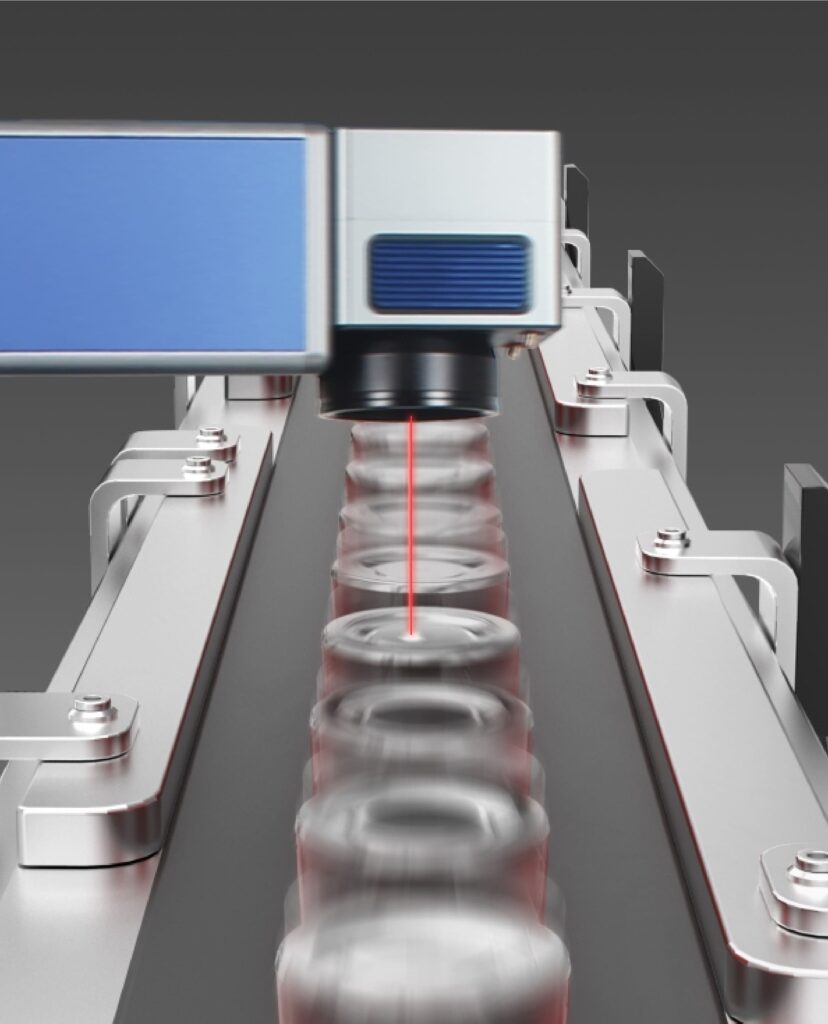

Laser marking is a permanent and durable marking method that withstands harsh environmental conditions, including heat, chemicals, and abrasion. The speed and efficiency of laser marking machines increase productivity and throughput, reducing processing times and enhancing overall operational efficiency. Additionally, laser marking is a versatile process that can be easily automated for continuous production lines.

The ability to mark a wide range of materials, including metals, plastics, ceramics, and composites, makes laser marking machines suitable for diverse industrial applications. Laser marking offers high contrast, readability, and aesthetic appeal, making it ideal for branding, serialization, and customization of products. Overall, the benefits of laser marking machines contribute to improved quality control, product identification, and customer satisfaction.

5. Factors to Consider When Choosing a Laser Marking Machine

When selecting a laser marking machine for your industrial processes, several key factors should be taken into account to ensure optimal performance and compatibility. Consider the type of material you will be marking and choose a laser source that is suitable for that material, whether it’s metal, plastic, glass, or organic substances.

Evaluate the required marking speed and resolution based on your production needs and quality standards. The size of the marking area, laser power, and focal lens options are crucial factors that determine the machine’s capabilities and flexibility in handling different marking tasks. Additionally, consider the ease of integration with existing production lines and the level of automation required for seamless operation.

Maintenance requirements, service support, and software compatibility are essential considerations to ensure the longevity and reliability of the laser marking machine. Cost considerations, including initial investment, operational expenses, and potential return on investment, should also be factored into the decision-making process. By carefully assessing these factors, you can select the right laser marking machine that meets your specific requirements and maximizes operational efficiency.

6. Maintenance and Troubleshooting of Laser Marking Machines

Proper maintenance of laser marking machines is essential to ensure consistent performance, longevity, and quality of markings. Regular cleaning of the laser optics, focusing lens, and exhaust system helps prevent debris buildup and maintains optimal laser beam quality. Calibration of the machine’s parameters, such as laser power, speed, and frequency, should be performed periodically to ensure accurate and reliable marking results.

Routine inspections of the cooling system, power supply, and motion control components help identify potential issues early and prevent downtime. In case of any malfunctions or errors, troubleshooting procedures should be followed to diagnose and resolve the problem promptly. Consult the machine’s user manual, technical support resources, or trained professionals for guidance on troubleshooting common issues.

Training operators and maintenance personnel on proper machine operation, safety precautions, and maintenance procedures is crucial for maximizing the lifespan and efficiency of the laser marking machine. Implementing a preventive maintenance schedule and keeping detailed records of maintenance activities can help track the machine’s performance and identify any recurring issues for timely resolution.

7. Integration of Laser Marking Machines in Industrial Processes

The integration of laser marking machines into industrial processes offers numerous benefits in terms of efficiency, quality control, and traceability. By incorporating laser marking technology into production lines, manufacturers can streamline marking operations, reduce manual labor, and increase throughput. Automated laser marking systems can handle high volumes of marking tasks with precision and consistency.

Integrating laser marking machines with other manufacturing equipment, such as CNC machines, robots, or conveyors, enables seamless data exchange and synchronization of marking processes. Real-time monitoring and feedback systems can be implemented to track marking quality, detect errors, and provide instant notifications for corrective actions. This integration enhances overall process visibility and control, leading to improved productivity and operational efficiency.

Advanced software solutions, such as CAD/CAM software and production management systems, can be integrated with laser marking machines to optimize marking designs, scheduling, and data management. Barcode readers, vision systems, and RFID technology can be integrated for automated identification, verification, and tracking of marked products throughout the supply chain. By leveraging the integration capabilities of laser marking machines, manufacturers can achieve higher levels of productivity, quality assurance, and customer satisfaction.

8. Cost Considerations for Laser Marking Machines

When assessing the cost of implementing laser marking machines in industrial processes, various factors should be considered to determine the total cost of ownership and potential return on investment. The initial cost of the laser marking machine, including hardware, software, accessories, and installation, is a significant upfront investment that needs to be balanced with the long-term benefits it provides.

Operational costs, such as energy consumption, maintenance, consumables, and labor, should be factored into the overall cost analysis. Calculating the cost per mark or cost per unit produced can help evaluate the efficiency and cost-effectiveness of using laser marking machines compared to traditional marking methods. Consider the savings in material waste, reduced rework, and improved quality control that laser marking machines offer.

ROI calculations should take into account the increase in productivity, throughput, and quality achieved by implementing laser marking technology. The potential for customization, scalability, and future-proofing of the equipment should also be considered when assessing the overall value proposition of laser marking machines. By conducting a thorough cost-benefit analysis, you can make informed decisions regarding the investment in laser marking technology and its impact on your bottom line.

9. Conclusion: The Future of Laser Marking Machines in Industrial Processes

As we conclude this ultimate guide to laser marking machines, it’s evident that these cutting-edge technologies are transforming industrial processes with their precision, efficiency, and versatility. Laser marking machines have become indispensable tools in various industries, offering unmatched capabilities in marking, engraving, and branding a wide range of materials.

The future of laser marking machines in industrial processes is promising, with ongoing advancements in laser technology, automation, and integration capabilities. Manufacturers are increasingly adopting laser marking machines to enhance productivity, quality control, and traceability in their operations. The ability to mark complex designs, alphanumeric codes, and graphics with high precision and speed makes laser marking machines the preferred choice for modern industrial applications.

By understanding the different types of laser marking machines, their applications, advantages, and integration possibilities, industrial businesses can leverage the power of laser technology to stay ahead in a competitive market. Embracing laser marking machines not only improves operational efficiency and product quality but also opens up new opportunities for innovation and customization.

In conclusion, laser marking machines are paving the way for a more efficient, precise, and sustainable future in industrial processes. By harnessing the capabilities of laser technology, businesses can elevate their marking operations to new heights of excellence and drive success in an ever-evolving industrial landscape. Make your mark with laser technology and witness the transformative impact it can have on your industrial processes.