Welcome to the ultimate guide to UV laser marking machines. Whether you’re in the manufacturing industry or simply curious about this technology, this comprehensive guide will provide you with everything you need to know. From the basics of UV laser marking to its applications and benefits, we’ve got you covered.

In this guide, we’ll delve into the intricacies of UV laser marking machines, exploring how they work and the different types available in the market. We’ll also discuss the advantages of UV laser marking over other marking methods, such as its ability to produce high-quality, permanent, and precise marks on a wide range of materials.

Additionally, we’ll explore the applications of UV laser marking machines across various industries, including electronics, medical devices, automotive, and more. You’ll discover how this technology is revolutionizing the way products are marked, providing durability, traceability, and added value.

So, whether you’re considering investing in a UV laser marking machine or simply want to expand your knowledge on the subject, this guide is your go-to resource. Get ready to unlock the potential of UV laser marking and take your marking capabilities to the next level. Let’s dive in!

1. How do UV laser marking machines work?

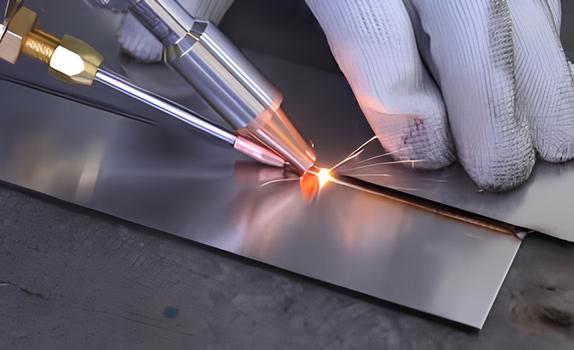

UV laser marking machines utilize the power of ultraviolet (UV) light to create permanent, high-quality marks on a wide range of materials. The process begins with a UV laser source, which generates a beam of concentrated UV light. This beam is then directed and focused onto the surface of the material that needs to be marked, typically using a series of mirrors and lenses.

The UV laser light interacts with the material at a molecular level, causing a photochemical reaction that results in a permanent mark or engraving. The intensity and duration of the laser exposure can be precisely controlled to create intricate designs, text, or barcodes on the surface of the material. Unlike traditional mechanical engraving or stamping methods, UV laser marking does not physically remove material from the surface, resulting in a clean, high-resolution mark that is both durable and aesthetically pleasing.

The versatility of UV laser marking machines lies in their ability to work with a variety of materials, including metals, plastics, ceramics, and even organic materials like wood or leather. The specific parameters of the laser, such as wavelength, power, and pulse duration, can be tailored to the specific characteristics of the material being marked, ensuring optimal results every time. This flexibility makes UV laser marking a valuable tool for manufacturers, designers, and engineers across a wide range of industries.

2. Applications of UV laser marking machines

UV laser marking machines have a diverse range of applications across numerous industries, making them an invaluable tool for a wide variety of businesses and organizations. One of the primary applications is in the electronics industry, where UV laser marking is used to create permanent, high-resolution serial numbers, barcodes, and other identifying information on electronic components, circuit boards, and even delicate semiconductor devices.

In the medical device industry, UV laser marking is crucial for ensuring the traceability and safety of implants, surgical instruments, and other medical equipment. The ability to precisely mark these items with unique identification codes, lot numbers, and other critical information helps to improve patient safety, streamline inventory management, and comply with regulatory requirements.

Automotive manufacturers also rely on UV laser marking to mark various components, from engine parts to interior trim, with unique identifiers and branding. This not only enhances the overall quality and appearance of the vehicle but also simplifies the manufacturing process and facilitates efficient supply chain management. Additionally, UV laser marking is used to create permanent VIN (Vehicle Identification Number) plates, ensuring the traceability and authenticity of each vehicle.

3. Advantages of UV laser marking machines

One of the primary advantages of UV laser marking machines is their ability to produce high-quality, permanent marks on a wide range of materials. Unlike traditional marking methods, such as ink printing or mechanical engraving, UV laser marking creates a mark that is resistant to fading, abrasion, and even chemical exposure, ensuring the longevity and durability of the markings.

Another key benefit of UV laser marking is its precision and flexibility. The laser can be programmed to create intricate designs, text, and barcodes with exceptional accuracy and detail, making it an ideal solution for applications that require high-resolution markings. Additionally, the non-contact nature of the laser marking process allows for the creation of marks on complex or irregular surfaces, expanding the range of materials and applications that can be accommodated.

UV laser marking also offers significant advantages in terms of speed and efficiency. The process is generally faster than traditional marking methods, allowing for increased productivity and throughput. Furthermore, the lack of physical contact with the material being marked means that there is no risk of damage or distortion, reducing the need for post-processing and improving the overall quality of the final product.

4. Factors to consider when choosing a UV laser marking machine

When selecting a UV laser marking machine for your business, there are several key factors to consider to ensure that you choose the right solution for your specific needs. One of the most important considerations is the type of materials you need to mark, as different laser wavelengths and power levels may be required for different materials.

Another crucial factor is the size and complexity of the marks you need to create. If you require high-resolution, intricate designs or barcodes, you’ll need to look for a machine with advanced laser technology and precision control capabilities. Conversely, if you only need to mark simple text or basic graphics, a more basic UV laser marking machine may be sufficient.

The speed and throughput of the machine are also important factors, especially if you have high-volume production requirements. Look for machines with features like automated part handling, multiple marking heads, or advanced motion control systems to maximize your productivity and efficiency.

5. Maintenance and troubleshooting tips for UV laser marking machines

Proper maintenance and regular troubleshooting are essential for ensuring the long-term performance and reliability of your UV laser marking machine. One of the most critical maintenance tasks is to keep the laser optics clean and free from any debris or contaminants, as even minor imperfections can significantly impact the quality and consistency of the marks.

Regular calibration and alignment of the laser, mirrors, and lenses are also crucial to maintaining optimal performance. This may involve adjusting the beam focus, checking the laser power output, and verifying the accuracy of the marking patterns. It’s important to follow the manufacturer’s recommended maintenance schedule and use only approved cleaning materials and procedures to avoid any damage to the sensitive components.

In the event of a malfunction or unexpected performance issue, it’s essential to have a clear troubleshooting process in place. This may involve checking for any error codes or warning messages, inspecting the physical components for signs of wear or damage, and systematically testing the various subsystems to identify the root cause of the problem. By having a well-documented troubleshooting protocol and access to comprehensive technical support, you can minimize downtime and ensure the continued reliability of your UV laser marking machine.

6. Comparison between UV laser marking machines and other marking technologies

While UV laser marking machines offer a range of advantages, it’s important to understand how they compare to other marking technologies in terms of performance, cost, and suitability for different applications. One of the primary advantages of UV laser marking is its ability to produce high-quality, permanent marks on a wide variety of materials, including those that are difficult to mark using traditional methods.

In contrast, mechanical engraving or stamping techniques can be limited in the types of materials they can effectively mark, and the resulting marks may be less durable or aesthetically pleasing. Ink-based marking methods, such as inkjet or pad printing, can provide a more cost-effective solution for some applications, but the marks may be less resistant to fading, abrasion, or environmental factors.

UV laser marking also offers superior precision and flexibility, allowing for the creation of intricate designs and barcodes that are not easily achievable with other marking technologies. This makes UV laser marking an ideal choice for applications that require high-resolution, permanent identification, such as in the electronics, medical device, or automotive industries.

7. Cost and investment considerations for UV laser marking machines

The cost of a UV laser marking machine can vary significantly depending on the specific features, capabilities, and brand of the equipment. In general, entry-level UV laser marking machines can be purchased for anywhere from $20,000 to $50,000, while more advanced, high-end models can cost upwards of $100,000 or more.

When considering the investment in a UV laser marking machine, it’s important to factor in not only the initial purchase price but also the ongoing operational and maintenance costs. These may include the cost of consumables, such as replacement laser tubes or mirrors, as well as the energy consumption and any required maintenance or service contracts.

However, it’s important to weigh the initial investment against the long-term benefits and cost savings that a UV laser marking machine can provide. By improving productivity, enhancing product quality, and enabling more efficient supply chain management, a UV laser marking machine can deliver a strong return on investment over time, especially for businesses with high-volume production or stringent traceability requirements.

8. Conclusion: Is a UV laser marking machine right for your business?

In conclusion, UV laser marking machines offer a powerful and versatile solution for a wide range of industries and applications. With their ability to produce high-quality, permanent marks on a diverse array of materials, UV laser marking technology has become an increasingly valuable tool for manufacturers, designers, and engineers who require reliable, durable, and precise identification and marking capabilities.

Whether you’re looking to improve traceability and compliance in the medical device industry, enhance the quality and appearance of your automotive components, or streamline your electronics manufacturing process, a UV laser marking machine could be the answer you’ve been searching for. By carefully considering the specific needs of your business, the types of materials you work with, and the level of precision and flexibility required, you can choose the right UV laser marking machine to unlock the full potential of this transformative technology.

As you evaluate the benefits and investment considerations of a UV laser marking machine, keep in mind that this technology is rapidly evolving, with new advancements and innovations constantly emerging. By staying informed, seeking expert guidance, and making a strategic investment, you can position your business for long-term success and take your marking capabilities to new heights. So, what are you waiting for? Explore the world of UV laser marking and discover how it can revolutionize your operations.