The diamond industry has always been synonymous with luxury, precision, and authenticity. In this competitive field, laser marking has emerged as a vital technology to enhance branding, ensure traceability, and add value to diamond products. Among the various marking technologies, UV laser marking stands out for its unmatched precision and ability to create permanent, non-invasive markings on high-value materials like diamonds. This article explores how UV laser marking transforms diamond customization and authentication processes.

UV lasers operate at a short wavelength, allowing them to engrave fine details without causing thermal damage to the diamond’s structure. The technology enables the creation of ultra-small text, serial numbers, or intricate logos, which are invisible to the naked eye but can be viewed under magnification. By etching permanent identifiers, UV laser marking ensures that diamonds are traceable and genuine, deterring counterfeiters.

1. The Importance of Marking in the Diamond Industry

Marking plays a crucial role in the diamond sector by serving multiple purposes:

- Authenticity: Engraving unique identifiers, such as GIA numbers, ensures the genuineness of diamonds.

- Traceability: Proper markings help track a diamond’s journey from mining to retail.

- Brand Enhancement: Luxury brands can etch logos or custom designs, adding a personalized touch to their products.

- Counterfeit Prevention: Laser markings make it easier to identify fake diamonds, protecting both businesses and consumers.

UV laser technology meets the industry’s demand for high-precision, non-invasive marking solutions.

2. Key Benefits of UV Laser Marking for Diamonds

- Damage-Free Precision

UV lasers operate at a short wavelength, allowing them to engrave fine details without causing thermal damage to the diamond’s structure. - High-Resolution Markings

The technology enables the creation of ultra-small text, serial numbers, or intricate logos, which are invisible to the naked eye but can be viewed under magnification. - Anti-Counterfeit Security

By etching permanent identifiers, UV laser marking ensures that diamonds are traceable and genuine, deterring counterfeiters. - Durability

Laser markings are permanent and do not fade over time, maintaining the diamond’s value and authenticity.

3. Applications of UV Laser Marking on Diamonds

- Jewelry Branding: Custom designs, logos, or even personalized messages for clients.

- Certification Numbers: Engraving GIA or other certification numbers directly onto diamonds.

- Luxury Packaging: Marking diamond containers or boxes with logos or tracking details.

- High-End Customization: Creating intricate, bespoke engravings for premium customers.

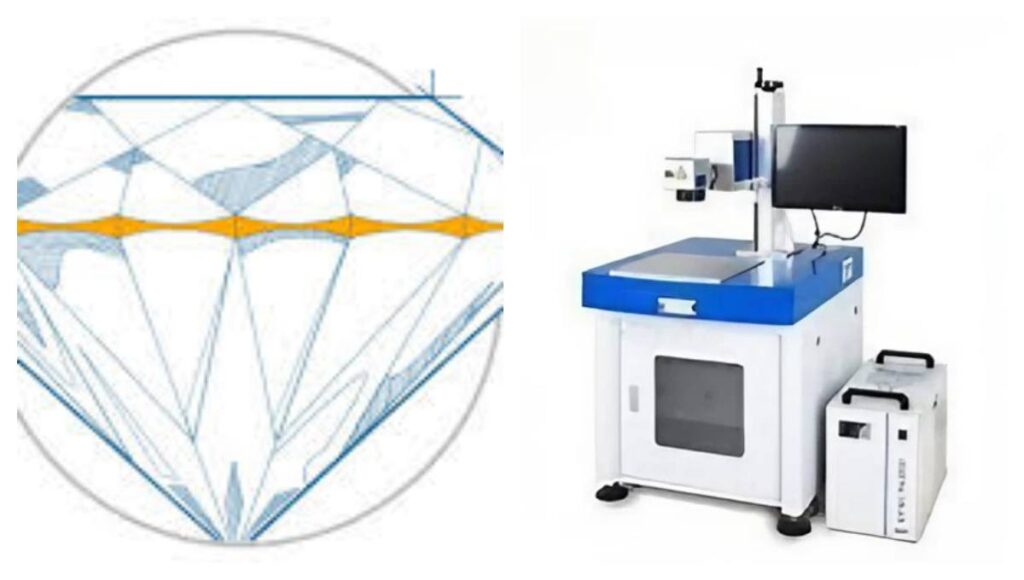

4. How UV Laser Marking Machines Work on Diamonds

UV laser marking operates by using a focused ultraviolet beam with a wavelength of around 355 nm. This precise energy level interacts with the diamond’s surface, creating micro-level indentations. The process is cold, meaning it avoids generating heat that could damage the material. Compared to traditional methods like acid etching, UV lasers offer:

- Higher accuracy

- Faster processing times

- Environmentally friendly operation

5. Choosing the Right UV Laser Marking Machine for Diamonds

When selecting a machine for diamond marking, key considerations include:

- Wavelength: UV lasers with a 355 nm wavelength are ideal for fine and cold marking.

- Software Compatibility: User-friendly interfaces and compatibility with design software enhance usability.

- Durability: Machines designed for long-term, high-precision use are better suited for luxury industries.

6. Conclusion

UV laser marking machines have revolutionized the diamond industry by offering precise, non-damaging, and permanent marking solutions. This technology ensures authenticity, enhances branding, and adds an extra layer of security against counterfeiting. Businesses in the diamond sector can greatly benefit from adopting UV laser technology, setting themselves apart in a highly competitive market.